Hi Readers. I had been asked a lot lately about high-end digital printing and how it is emerging into the printing industry today. At one time, digital printing was really good to quick print shops, in-plant print shops in offices. Well, in the mid-1990s, all of these changed with the advent of high volume print devices. Generally, those that printed over hundred pages per minute such as the Indigo, iGen, Zycon and Express.

So how does digital technology coexist with offset?

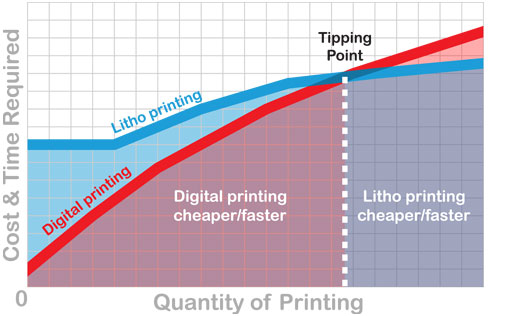

Well, during the mid-1990s for offset to compete, it needed to run several thousand impressions to match digital in cost. The advent of digital technology such as computer-to-plate systems, digital work flows, etcetera, has changed a landscape for offset to better compete with digital. However, digital work continue to make inroads due to its flexibility. Before I get into semantics, looking at offset and digital printing, let’s look at the advantages of each technology.

What are the offset/Litho advantages:

Okay, so what are the offset advantages? Well, very high image quality. It can print on a high range of substrates such as paper, plastic and film, etcetera. No qualification process is needed for substrates in most cases. The unit cost of a project goes down as the volume goes up. Depending upon the size of the press, can print large formats. Much faster printing process than digital. Much better reproducing Pantone or special colors. Can do varnishes and coatings inline.

What’s the digital advantages:

What’s the digital advantages? Short turnaround time. Flexibility, every print can either be the same, different or parts can be the same and other parts be different. Can do short run Variable Data Printing. Less waste due to minimal make-ready with more accurate counts. Cheaper for low volume printing than conventional printing. While image quality is less than that of offset, the differences today are small and depending upon the job in the high-end press used, may not be noticed by the client or their customers. Good color control top-to-bottom since you are printing inline and both at the same time, and there is no fountain ink balance like you have with offset. Can use, in most cases, any software from word-processors to high-end print software. In fact, digital loves PDFs. Can proof right on the digital press. Plus, the proof is extremely accurate.

Now let’s get a better look at the two printing technologies. There are a lot of high-end digital presses on the market. With some in this category being the HP Indigo Series, which uses a liquid toner. The Kodak Express, Xerox iGen, and Zycon Series presses. All of which use a dry toner.

To see which each technology fits in the printing market, I decided to price out a typical job using a local printer who prints sheet feed offset in digital. Keep in mind sheet feed is more to compete against digital where high speed web offset is not, since the web is designed for high volume constant speed. This, of course, is different when you talk about the converting market and transactional printing and inkjet web technology is a subject which I will cover in another digital episode.

If you want to print urgent print job digital is your best choice like Same Day Banner printing London

Or Custom Art Printing.

It is clear that offset and digital technology both have a place in the printing industry today. To give you an idea of each technology in this comparison, the offset press being used is a six color med-format press and the digital press in HP Indigo 5500. The overall pricing can vary depending upon the area the country the digital and offset press is used.

How this prices out:

So, let’s see how this prices out. Okay, the job in question is an 8 page folded saddle-stitched soft covered printing 4/4 on a 70 pound text on such as , if I print a hundred copies, digital is by far the less expensive way to go. Look what happens when the amount reaches at 500 copy range. All of a sudden, offset starts to get less expensive. At a 2500 count level, offset is by far a less expensive way to go. You can see as the count rises, offset becomes less expensive. This, of course, is because digital printing today is still much slower than offset as well as using smaller sheet sizes.

Size of Printing:

While the average offset press size is in the range of 29 inches, it provides a larger sheet size. The high-end digital presses range more on an average in the 14 x 20 sheet size range. Now, with that being said, a printer might have another job. Let’s say, the client wants 648 copies of a 44 page booklet printed 4/4. The job calls for using a 50 pound stock for the text pages and a 65 pound cover stock for the car. Now, that quantity and the amount of pages, you would think it would be best to print the job offset. Not true. That’s the print digital in this case. Why? With digital, I can print all the color pages top and bottom at once without any extra set of cost as I would have to do for offset. It says digital is self-contained color wise. I’ll print for example 10 text signatures comprising four pages each and one for the cover. There would be no, virtually no make-readies between signatures as well.

Why digital?

Why digital? Why should I print this digital? Let’s find out. On the other side, if I was to print this job offset, I would have on a medium format press a total of 44 offset plate, printing 5 signatures for the text pages in a sheet wise configuration and it work in turn for the cover. This would amount to a total of 10 make-readies plus one for the cover. This high amount is because the job has to be turned and back printed to make up the 8 page signature. The process would also have to run 4 color process, which means setting up 4 units. The job would technically run far quicker than digital. But due to all plate changes and make-readies, the job would actually take much longer than digital to run overall.

You can also print presentation folder using digital printing.

Always check with your printer to see how they would like to print your job. You might be surprised. We know today that offset press runs are getting smaller and smaller. Instead of printing a hundred thousand copies, they may print 10,000 and come back later to print an additional amount, which saves them an inventory bulk material for use later as well as being able to change parts of a piece turn of reprint.

Today, the average run for sheetfed is around 5,000. For high-end digital, it is estimated that the average run is below 1,000. Keep in mind that these are just averages and apply only to the high-end digital market.

Okay. So where is digital going to fit in today’s changing markets? I believe it will be more in the personalized marketing area. Quick turn time or I need it now market. Short run jobs especially where there is not a lot of special colors needed. On demand books and photo books etcetera are naturals. Even though most digital presses have limited capabilities for true multi-spot color printing, some can do up to one, two or three spot colors. The nice thing about both technologies is that they can be combined. You can run a job offset for the static information and then take that and run the variable images on the offset portion digital.

Direct mailing, personalized marketing, for example, would be a prime example. Tickets, cars, etcetera would be another classic case. So what does this all mean? Let’s find out. So what does this mean? It means that digital printing can be the ultimate solution for some clients. But in my experience with computer to plate offset technology combined with the respectability of high quality stock and finishing, offset will yield a superior print quality. And will probably always be the trace for the runs over at least 1500. Of course, if you are looking for quick turnaround time in short runs and or variable imaging, then digital is your choice.

Keep in mind that two technologies can and always will work together, especially in a direct mail and marketing environment. It is clear to me that offset in digital will continue to co-exist but expressed on migration of digital printing technologies as maintenance and consumable costs go down, speeds and paper sizes go up. This begs the question of, will digital overtake offset? In my estimation, not now or in the near future. That case for now, geez, who knows?

Well, while both offer advantages and disadvantages, the two serve different, but sometimes the same markets, depending upon the job and the quantity to be printed. Each technology, whether it be offset or digital can do the job depending on what you’re looking for, and that’s the key. What are you looking for in your job? Short run, variable imaging, low volume? Digital is your choice. However, if you are looking at a high count job or a job with specialized paper on conventional printing such as offset, it is definitely your choice. You can always talk to your printer for advice.

For a printer, digital technology by the way offers them a chance to move their low volume jobs off their heavy metal presses, which frees them to put more higher volume jobs on. Well, I have a job I have to finish. It’s a direct mail piece, so part of it will be printed offset and the variable imaging part is going to be printed digital.

Hi! I’m Jon Tabner, I am a Graphic Designer and Marketing Executive in profession. Exploring new things, innovation and designing is my passion. Now working as head of Graphic Designing & Marketing Executive team at Print In London and currently I am based in London. I love using my design knowledge to inspire small businesses to think outside the box when designing their print.